All Of Our Instrumentation Fittings Carry A Manufacturer’s Lifetime Warranty, And Heat Codes Are Permanently Stamped On All Fittings For Traceability.

Featured Products

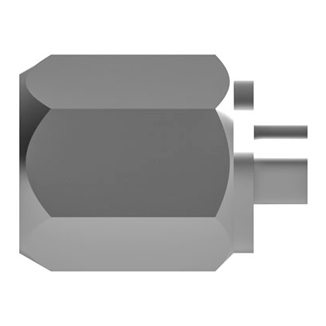

INSTRUMENTATION TUBE FITTINGS

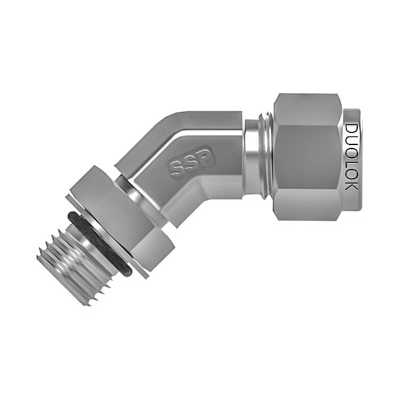

- 1DUOLOK TUBE FITTINGS

Dual ferrule gageable fittings manufactured to be interchangeable and intermixable with Swagelok® and Parker A-Lok® fitting series. Available in tube sizes 1/16” to 1” in both stainless steel and brass. Working pressure is equal to the maximum working pressure of the recommended tubing used with the fitting (except some specially designed or bored through fittings, or some configurations with “AN” or O-ring style ends).

- 2UNILOK TUBE FITTINGS

Single ferrule gageable fittings manufactured to be interchangeable and intermixable with Parker CPI® fitting series. Working pressure is equal to the maximum working pressure of the recommended tubing used with the fitting (except some specially designed or bored through fittings, or some configurations with “AN” or O-ring style ends. Also available in brass).

- 3GRIPLOK TUBE FITTINGS

Dual ferrule fittings manufactured to be interchangeable and intermixable with Hoke Gyrolok® fittings. Working pressure is equal to the maximum working pressure of the recommended tubing used with the fitting (except some specially designed or bored through fittings, or some configurations with “AN” or O-ring style ends). Also available in brass.